Revealing Defects in Belt Drive Systems

In this short video, Rob Dent (CMRP, CRL) from SDT, details the use of ultrasound technology to detect faults in belt drives.

One small but vital component of many machines is the belt sheave. Belt sheaves can sustain damage from everyday wear and tear, misalignment, and contamination.

The benefits of using ultrasound to find defects in belt sheaves:

- Early Detection: By regularly scanning belt sheaves with an ultrasound device, maintenance teams can detect unusual sounds that indicate wear or misalignment early on. This early detection allows for timely intervention before a minor issue becomes a major problem.

- Non-Invasive Check: Using ultrasound is non-invasive, meaning you don’t need to stop production to check the condition of the belt sheave. This makes the process quick and hassle-free.

- Precision: Ultrasound technology provides precise information about the condition of the belt sheave, helping maintenance teams pinpoint the exact problem and take appropriate action.

Using ultrasound to detect bad belt sheaves is a smart, efficient way to maintain machinery. It allows for early detection of issues, saving time, money, and increases safety.

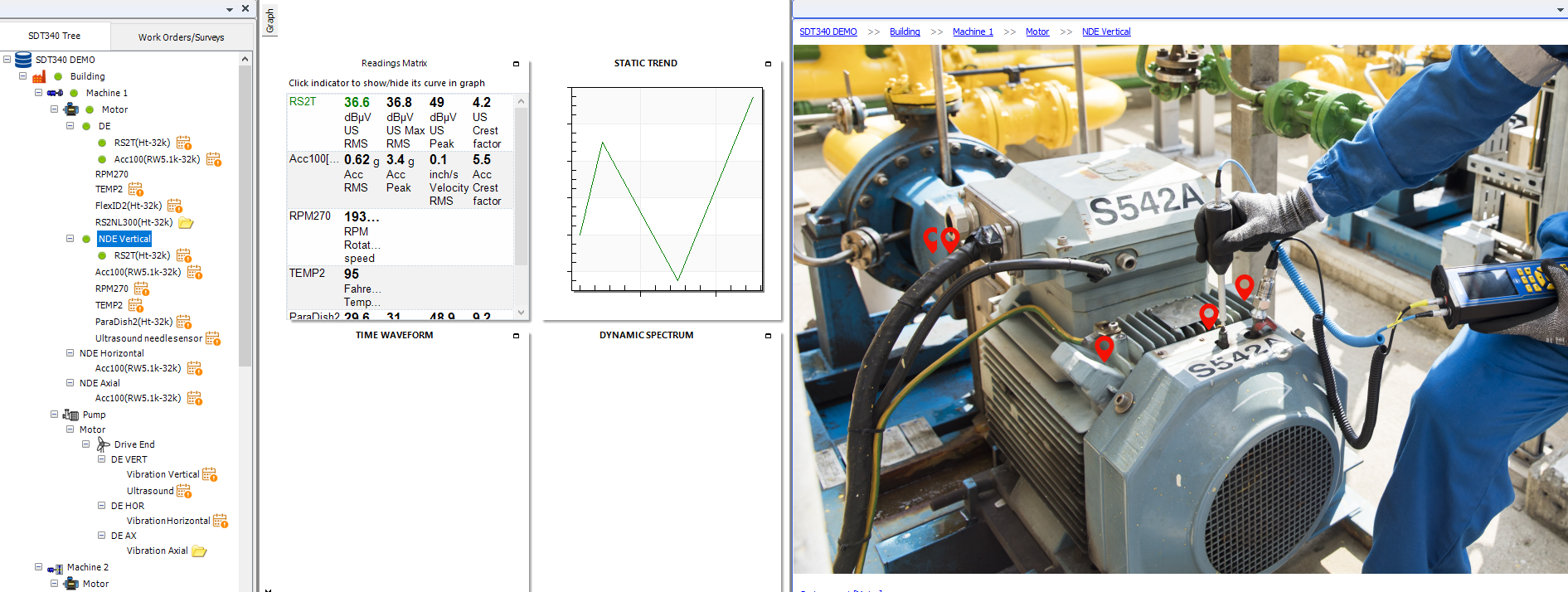

Our recommended SDT ultrasound tools for belt sheave inspection.