SDT Sonavu acoustic imaging camera

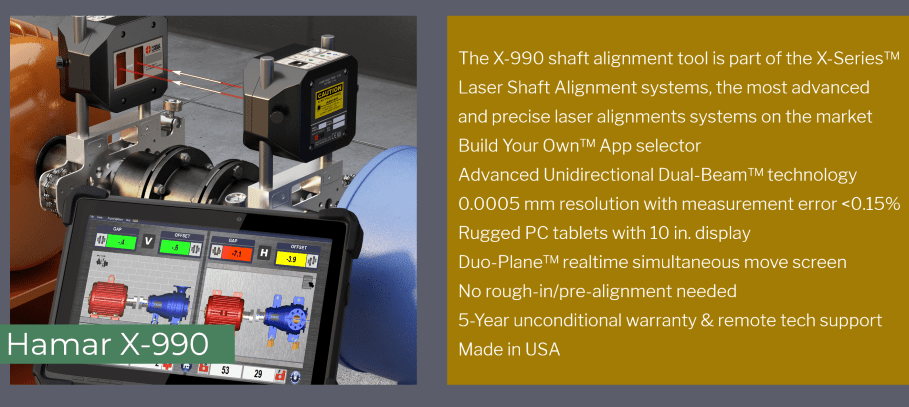

SDT Sonavu acoustic imaging camera Hamar X-990 Laser shaft alignment system

Hamar X-990 Laser shaft alignment system Precise Reliability Laser alignment service

Precise Reliability Laser alignment service SDT Vigilant online condition monitoring

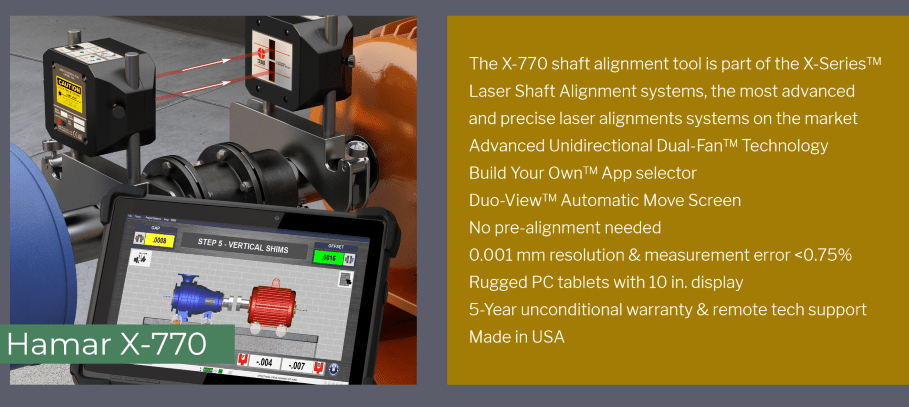

SDT Vigilant online condition monitoring Hamar X-770 Laser shaft alignment system

Hamar X-770 Laser shaft alignment system Precise Online Training

Precise Online Training SDT LeakChecker

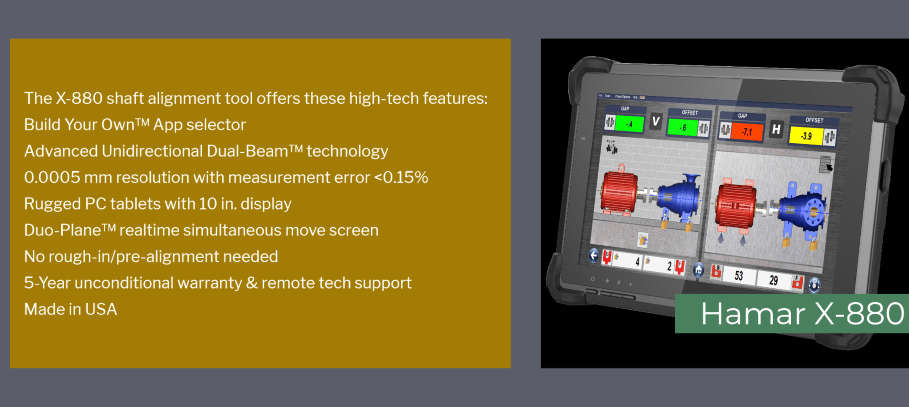

SDT LeakChecker Hamar X-880 Laser shaft alignment system

Hamar X-880 Laser shaft alignment system Precise Reliability On-site training

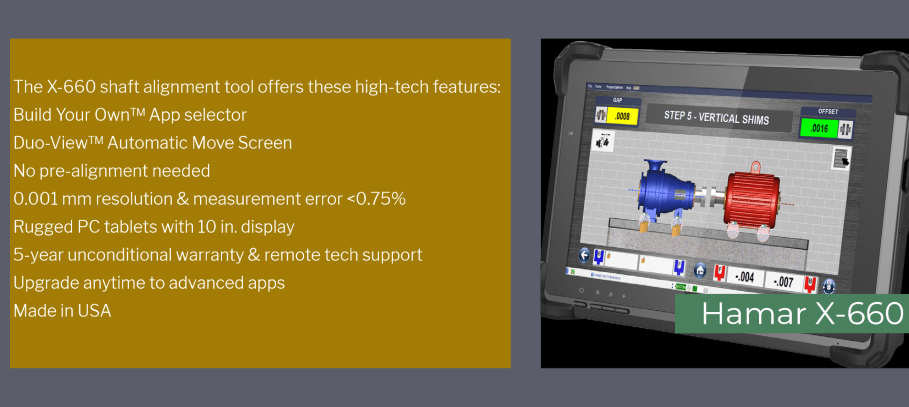

Precise Reliability On-site training Hamar X-660 Laser shaft alignment system

Hamar X-660 Laser shaft alignment system