This SDT270 is a full featured ultrasound tool. Measure ultrasound, temperature and RPM with on-board sensors and two sensor inputs for external ultrasound and vibration sensors and accessories. The 270 is great for measuring air and vacuum leaks, bearing condition and monitoring. You can also monitor valves, steam, hydraulic systems, electrical faults and valve monitoring. It uses four condition indicators (RMS, Max RMS, Peak and Crest Factor) to allow for more thorough diagnosis. Each ultrasound and vibration measurement also records a clear, accurate and scaled .wav audio file so the measurement can be listened to in the available UAS3 software as part of the analysis.

|

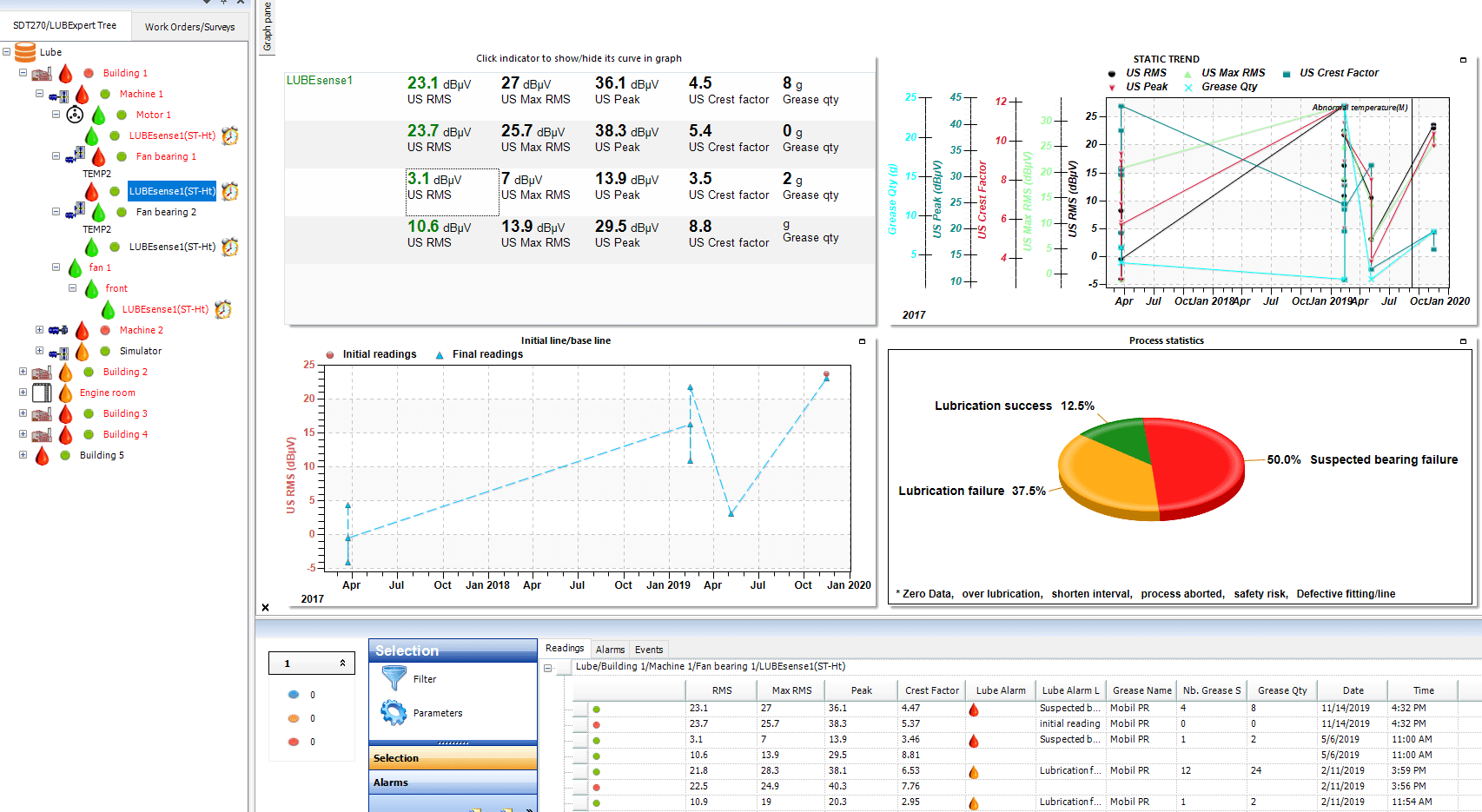

Mechanical Condition Monitoring Identify early-stage bearing defects to prevent unplanned failures. |

|

|

Bearing Lubrication Monitoring The right amount of lubricant at the right interval with acoustic lubrication |

|

|

Compressed Air & Gas Leak Detection Find Air Leaks. Decrease Energy Consumption. Maximize Uptime. |

|

|

Electrical Equipment Fault Detection Safely Inspect Electrical Systems with Ultrasound. |

| Steam Trap Testing and Maintenance

Keep Your Steam Clean, Safe And Energy-Efficient. |

|

|

Hydraulic Systems Monitoring Detect leakage, by-passing and blockages. |

|

| Valve Condition Monitoring

When your valves are closed, are they really closed? |

|

|

Tightness Testing Ultrasonic tightness testing offers a complete, global solution with unheard-of accuracy and reliability. |

Contact us for a demonstration or more information.

*FREE ground shipping in the continental US.

SDT340 ultrasound system(Opens in a new browser tab)