Thermal Growth

Machines may experience positional change from the time it is off-line to when it is running under normal operating conditions. Some of these changes are due to process forces( fluid pressures, airflow, etc.) and some may be cause by a change in the temperature of a machine. This is called thermal growth. These changes differ depending on the material used. The change can be minute or significant, depending on the temperature, size and make-up of the machine.

To calculate thermal growth the T x L x C formula is used. T represents the change in the materials temperature in degrees Fahrenheit, L represents the length in inches of the material from the machine base to the center line of the shaft, and C represents the materials coefficient of linear expansion. Different materials have different C values. Using the formula, the change in a machines shaft alignment can be anticipated based on the expected changes in machine temperature.

Thermal growth can not only impact a machine’s process but also its surroundings. Precise visited a hospital in Pennsylvania to resolve an issue with vibration in an operating room.

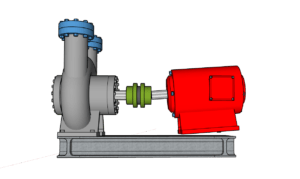

The visit was initiated because an operating room used for neurosurgery could not be utilized while the compressors for the hospital’s air conditioning were running due to a slight vibration in the floor. The room was located directly over the area that housed the compressors which caused the vibration so the compressors were turned off during the time the room was in use. The increase of vibration needed to be resolved to get back to normal working conditions.

We were able to trace the issue to a compressor by analyzing information gathered using a vibration data collector. The highest vibration came at both 1 times RPM and 2 times RPM. We then checked the alignment of the compressor to find that it was within tolerance while cold then checked for any positional change while running that may affect the alignment.

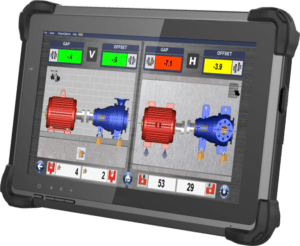

To do this, Precise, did a thermal growth survey with a laser shaft alignment system. This was accomplished by putting the laser on the drive machine housing and the detector on the driven machine housing and starting the machines to determine what thermal changes were causing the misalignment. By using a two-axis laser it was determined what vertical and horizontal offsets should be used for thermal targeting. The offsets were added to the cold alignment and the disruptive vibrations were significantly reduce allowing the room to be used while the machines were running.

Thermal Growth

is the tendency of matter to change its shape, area, volume, and density in response to a change in temperature. Applied to machinery this usually means frame expansion do to heat generation.

Formula

T x L x C. T represents the change in the materials temperature in degrees Fahrenheit, L represents the length in inches of the material, and C represents the materials coefficient of linear expansion.

Thermal Targeting

simply means that the shafts may be misaligned while at room temperature, but as they heat up to operating temperature, they will “grow” into alignment.

Laser Alignment

Use the Hamar Laser Alignment tools to align your machines right. We also offer thermal growth studies, geometric measurements and more.