THE HAMAR X-880, EXEMPLARY PERFORMANCE IN LASER SHAFT ALIGNMENT

UNPRECEDENTED SHAFT ALIGNMENT TECHNOLOGY

With a legacy spanning over five decades, Hamar has continually delivered exceptionally precise alignment systems across diverse industries and applications. Originating in the demanding machine tool industry, where precision and complexity abound, Hamar took a significant leap 30 years ago by introducing the world’s first 4-axis shaft alignment system. Drawing upon this wealth of experience and knowledge, we proudly present the X-880 Wireless 5-axis Shaft Alignment System – a culmination of insights that results in an unparalleled, user-friendly tool renowned for its accuracy.

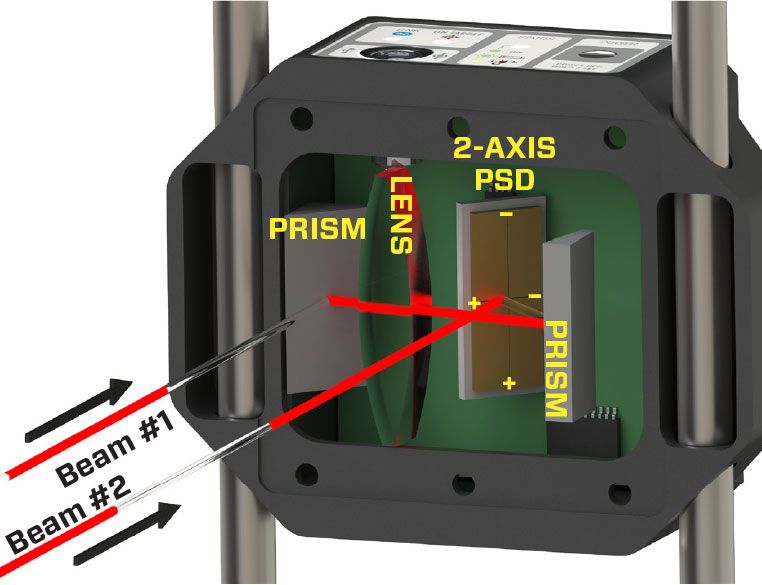

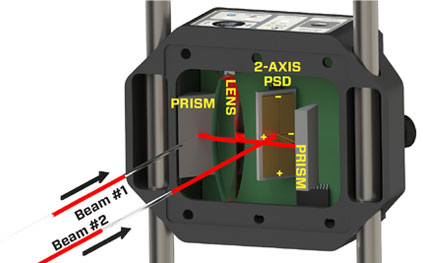

INNOVATIVE UNIDIRECTIONAL DUAL-BEAM™ TECHNOLOGY

At the heart of this innovation lies the remarkable Unidirectional Dual-Beam™ technology, boasting an impressive ± 12º angular range. This groundbreaking approach harnesses the power of two unidirectional laser beams (two lasers, one direction), effectively eliminating the complexities associated with “cross-fire” lasers (two lasers, two directions) during the initial rough-in phase. The outcome? Swift and effortless machine alignment, especially beneficial for extended-distance applications. Ultimately, this translates into greater efficiency, more completed tasks in less time, and heightened satisfaction for managers overseeing the process.

PRECISION WITHOUT ROUGH-IN PREP REQUIRED

In contrast to “cross-fire” laser alignment systems that mandate a preliminary rough-in or pre-alignment of the machinery before data capture can commence, our Dual-Beam™ technology revolutionizes the process. With its two unidirectional laser beams and a single 33 mm sensor, you can bypass the need for rough-in procedures. Simply affix the brackets, laser, and target, and you’re ready to dive into your alignment tasks with utmost efficiency!

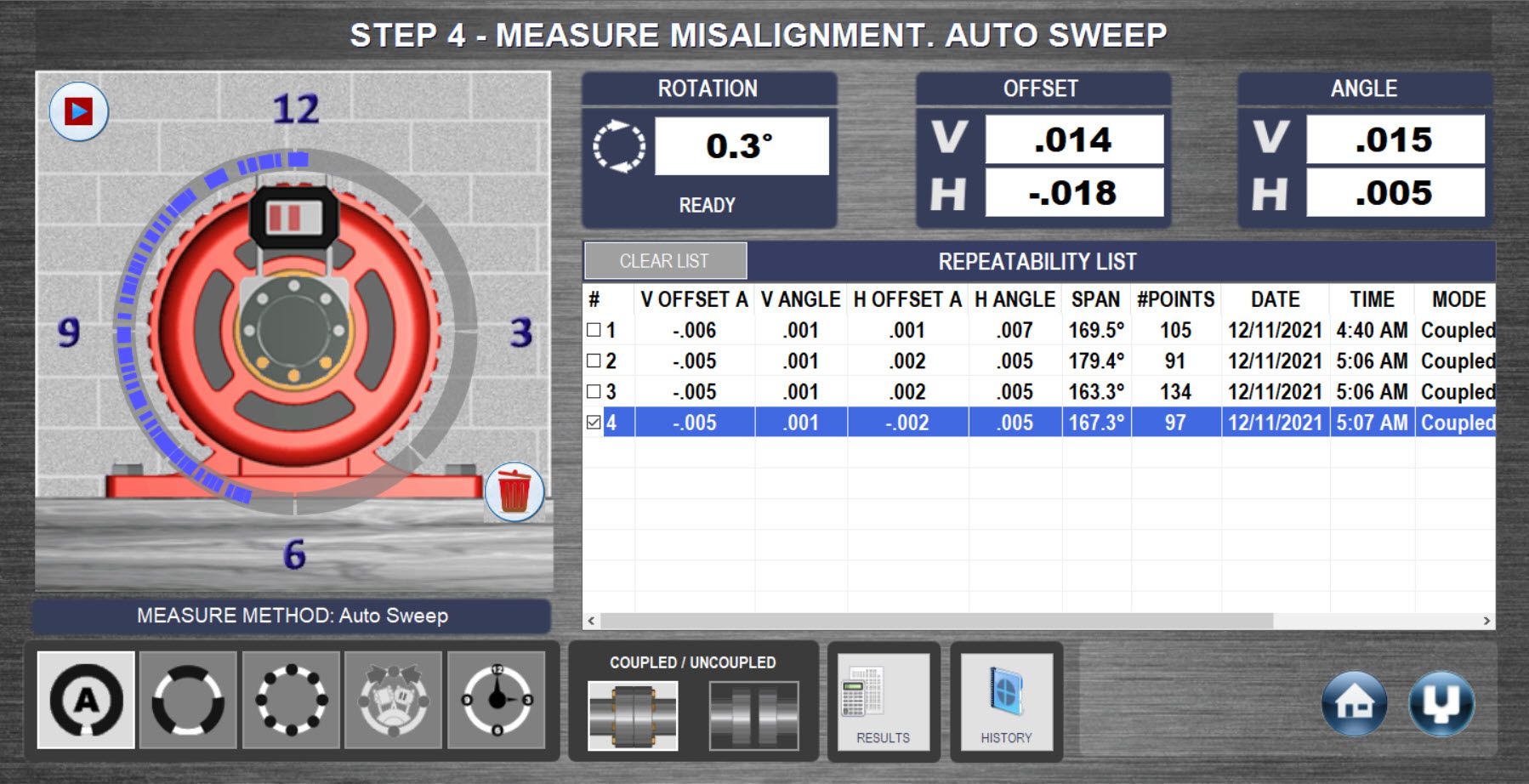

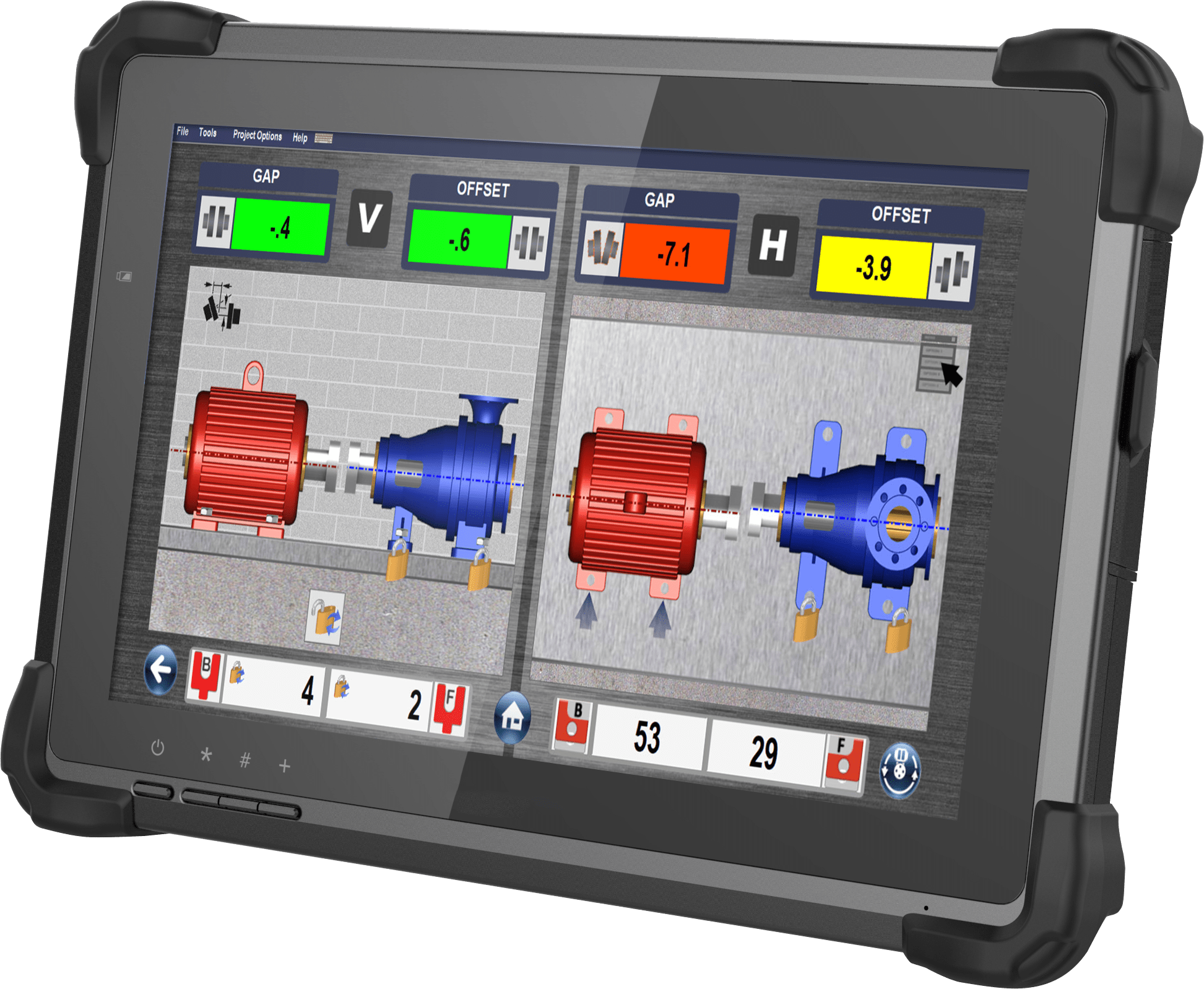

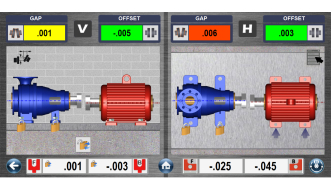

REAL-TIME DUO-PLANE™ SCREEN: ALIGNMENT ADJUSTMENTS WITHOUT SHAFT ROTATION

Our Duo-Plane™ real-time move screen, in conjunction with the 5-axis target, empowers you to access a live alignment screen for both the vertical and horizontal planes, encompassing vertical and horizontal offset and angle concurrently, all without the need to rotate the shafts. Furthermore, you have the flexibility to leave the shafts at virtually any desired rotation angle. This capability proves particularly invaluable in the context of sizable machinery, where shaft rotation poses challenges or where bolt tightening can induce horizontal machine movement, necessitating re-alignment.

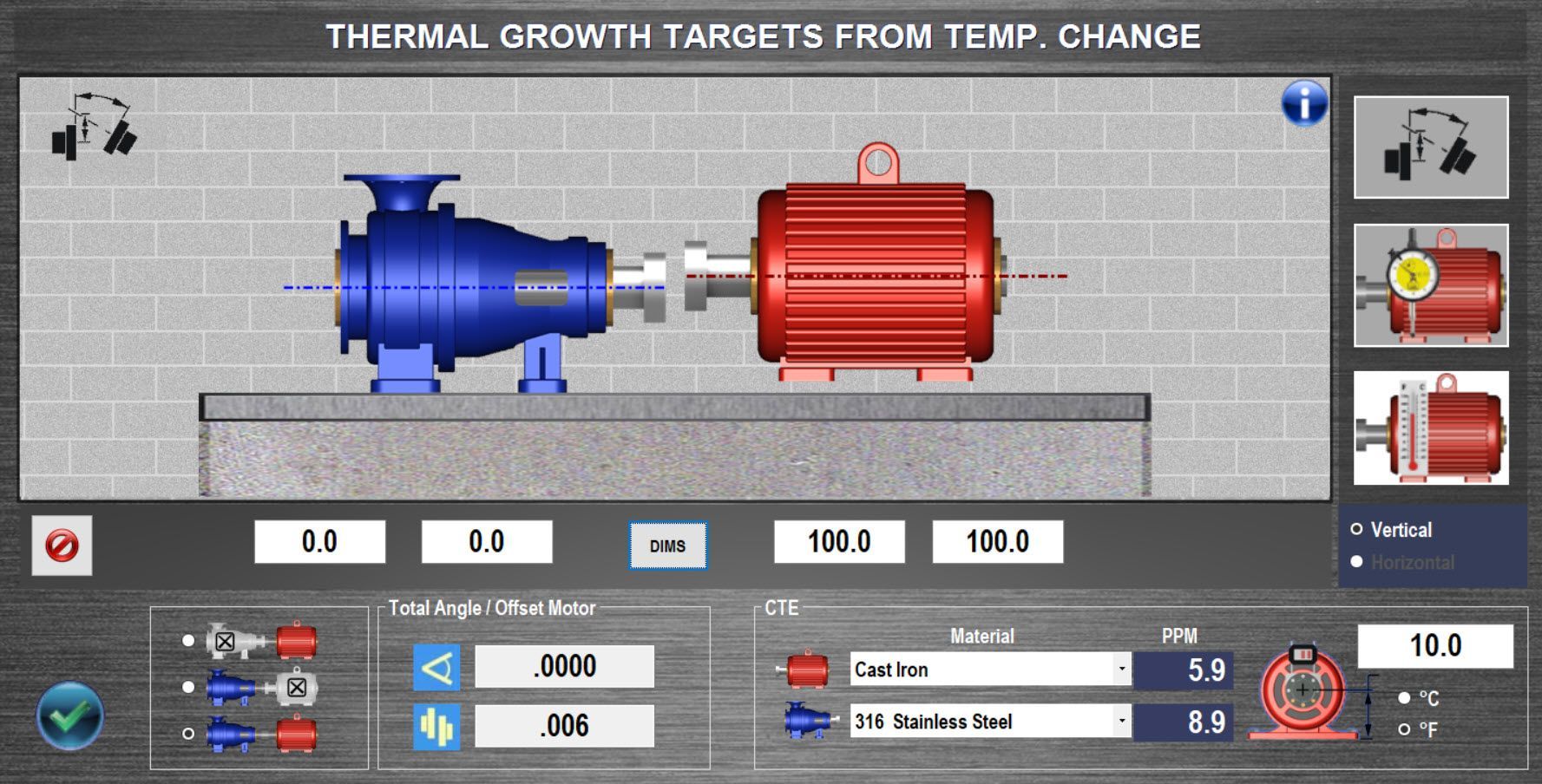

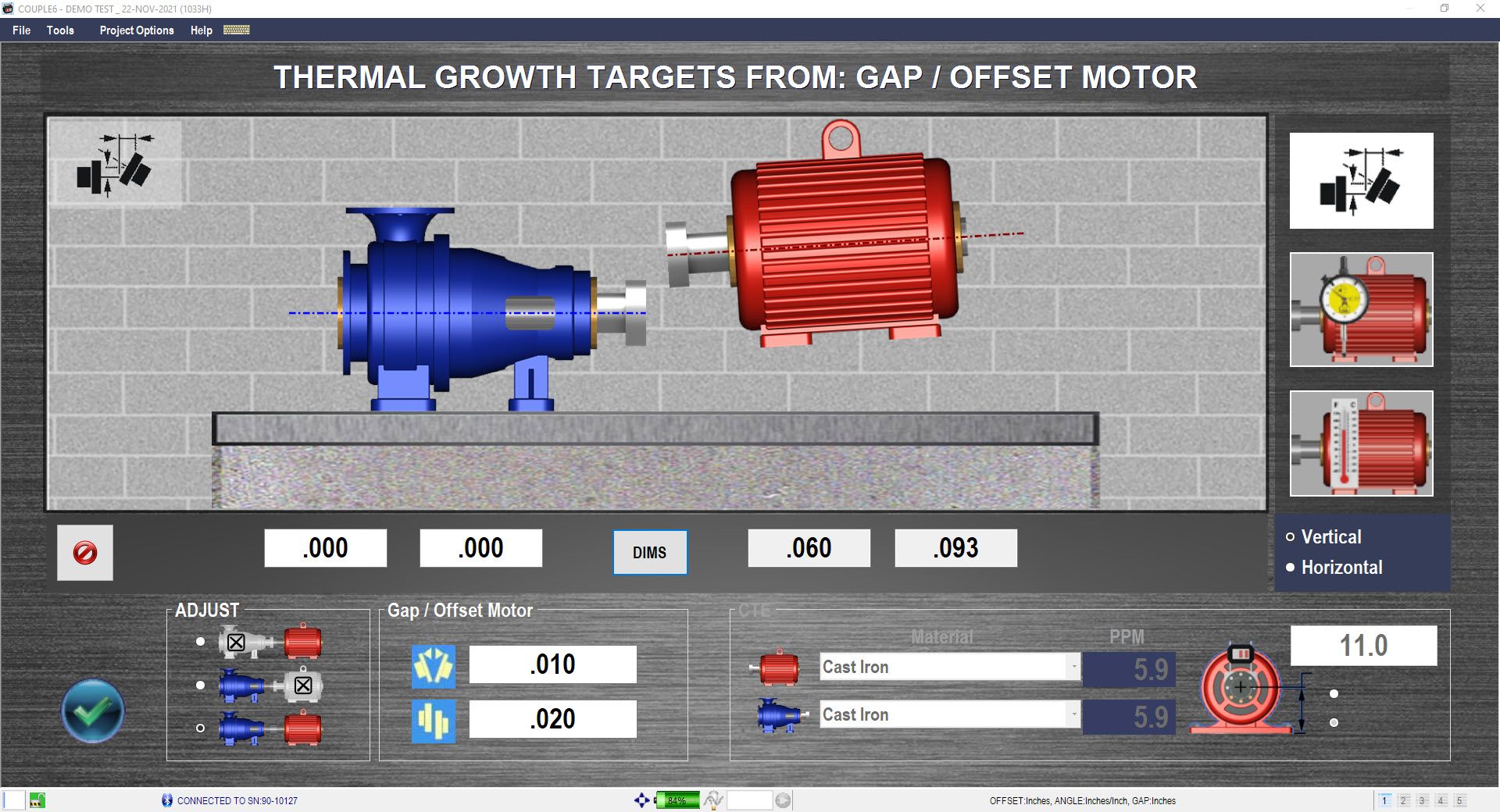

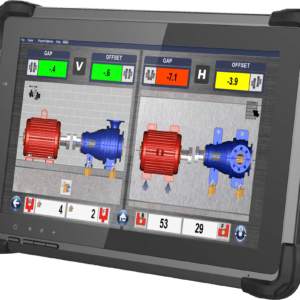

EFFORTLESS EASY-GUIDE™ NAVIGATION ENHANCED BY ONBOARD MANUAL AND TRAINING VIDEOS

The Couple6 software is characterized by our user-friendly Easy-Guide™ navigation, boasting intuitively designed, high-quality screens that seamlessly guide users through every facet of the alignment process. Furthermore, to address any potential queries or challenges, the software includes an integrated manual and a repository of training videos, readily accessible from within the program. With such user-centric features, the software is so remarkably straightforward that many customers find themselves confidently utilizing the X-880 kit immediately upon unboxing.

The Couple6 software is a robust shaft alignment program compatible with Win7/8/10 tablets or laptop PCs equipped with Bluetooth™ connectivity. Leveraging the capabilities of Windows tablets, you can harness the tablet’s power to effortlessly email reports directly from the field, run various reliability software, and access a multitude of other Windows-based applications. This versatility also ensures ease of replacement should any issues arise with the tablet device.

UNPARALLELED PRECISION FOR SWIFT ALIGNMENTS

When it comes to crucial machinery, excellence is the expectation, and the X-880 platform surpasses that standard. Thanks to super-linear PSD technology and an impressive 500-point linearization process, we’ve dramatically reduced the error rate to an astounding <0.15%. This level of precision stands out, being up to 15 times greater than that offered by our competitors. With this exceptional accuracy, you can trust that your motor alignment is achieved with unparalleled precision.

Enhanced accuracy also translates into superior repeatability and more precise shim calculations, sparing you from the need for repeated alignments. With “Shim Once, Move Once™,” you can optimize efficiency and minimize downtime, making the most of your valuable time and resources.

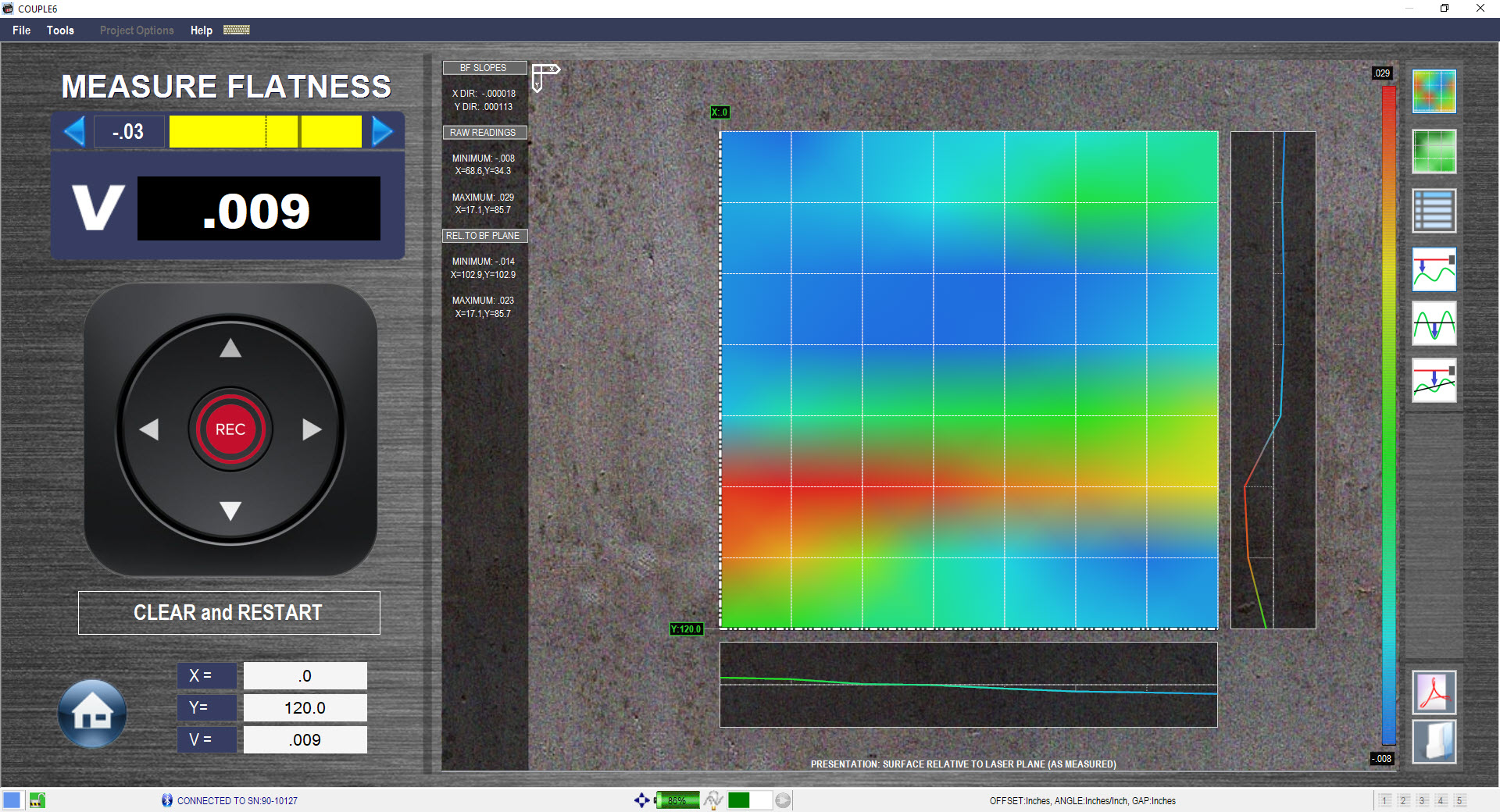

Available Flatness Measurement

Use the A-987 Base or the higher precision L-730/L-750 Leveling Lasers with the A-1519-2.4ZB Target to measure the flatness of sole plates, compressor frames and other surfaces. Couple6 calculates the Best Fit plane for the data to provide the overall flatness values. A report shows the flatness TIR, a graph and a table of data.

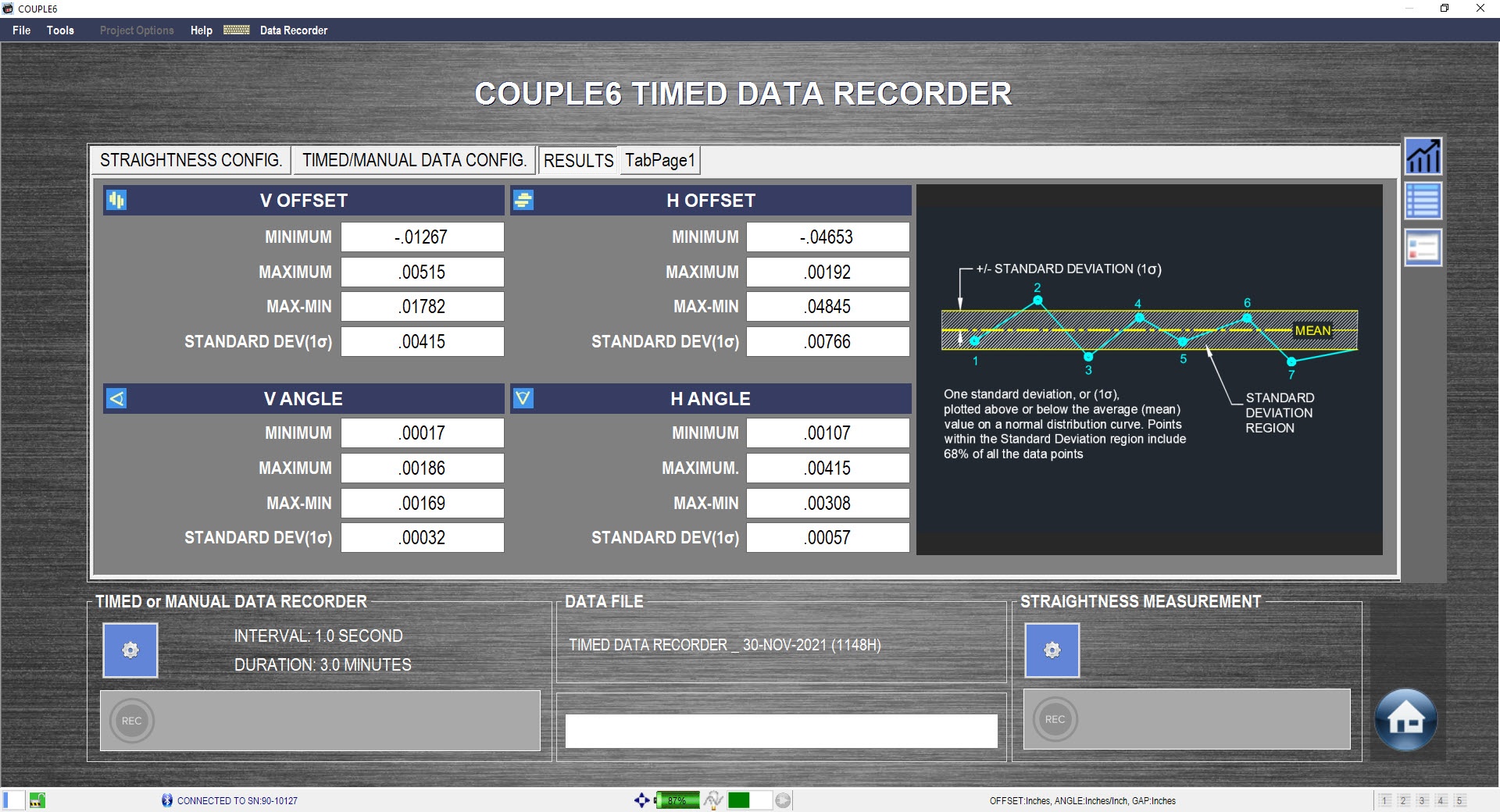

Available Straightness Measurement

Using the A-987 Base, you can use the shaft alignment lasers to check the vertical/horizontal straightness of rails and surfaces. The Couple6 software calculates the Best Fit line for the data to provide the overall straightness values. A report shows the straightness TIR, a graph and a table of data.

5-YEAR UNCONDITIONAL WARRANTY & COST-EFFECTIVE OWNERSHIP

Our 5-Year Unconditional Warranty stands apart from the competition, free from hidden fees and cumbersome conditions. It’s as straightforward as it sounds: no strings attached. Unless subjected to abusive misuse, any issues that arise are promptly addressed, either through replacement or repair. There’s no fine print or complex terms to navigate.

In addition to our transparent warranty policy, we pride ourselves on our commitment to cost-effective ownership. Unlike other systems, we do not impose software maintenance fees. You’ll enjoy complimentary software updates throughout the product’s lifetime, ensuring you always have access to the latest enhancements and features without incurring additional costs.

REMOTE TECHNICAL SUPPORT

Leveraging the capabilities of Windows, our technical support department can establish remote access to your tablet seamlessly, utilizing both WiFi and the Internet for efficient troubleshooting and assistance.

Training included

All Hamar Laser® X-880 laser shaft alignment systems purchased from Precise Reliability include 1-day of on-site training.

Contact us for more information or demonstration.

Made in USA