About Hamar’s Unidirectional Dual-Fan™ Technology

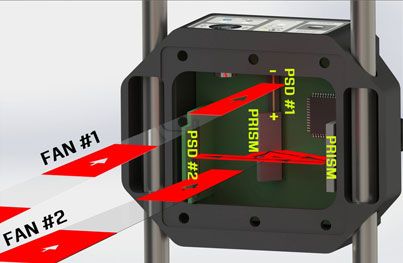

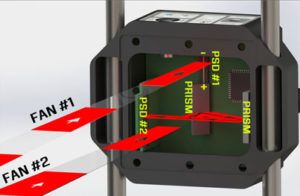

Hamar designed the unidirectional Dual Fan™ technology to be versatile and accurate for their entry-level shaft alignment systems. Dual-Fan™ technology allows highly accurate measurement of offset and angularity simultaneously, using two 0.5-degree laser fans and two 20 mm PSDs.

The Dual-Fan™ on the X Series™ X-660 and X-770 provides full angular measuring range over the entire operating area between laser and target.

Alignments can be challenging over very long or very short distances. With Dual-Fan™ technology, you get the same high, fixed angular resolution between heads whether they are 2 inches apart or 15 feet apart.

Hamar’s laser fans are very thin, which increases the measurement range of the PSD to handle larger alignment errors. They have very little divergence, with a maximum width of 3 inches at 15 feet, which improves laser safety.

Hamar’s Dual-Fan™ technology has ambient light correction by utilizing blinking laser fans to eliminate the effects of background light.

Provides highly accurate, simultaneous measurement of offset and angle, using two 0.25-degree laser fans and 2 PSD sensors, offering full angular measuring range over the entire operating range between laser and target.

Here’s how it works:

1. Fan #1 blinks on and hits PSD measuring the center offsets.

2. Fan #1 blinks off for ambient light correction.

3. Fan #2 blinks on and bounces off of 2 prisms and hits a second PSD that is in the same plane as the first. (The difference between the 2 PSD’s divided by beam path length produces the angle.)

4. Fan #2 blinks off for a second ambient light correction.