The X-880/X-990 are simply the most advanced laser systems in industry, bringing you unparalleled performance in the field.

The Hamar Laser® X-990 laser shaft alignment system Includes the L-790 Unidirectional Dual-Beam™ Laser, T-1290 5-axis Target, A-980 Stainless Steel Shaft Brackets, A-980A Chain Bracket Upgrade, Rugged 10” Tablet and heavy-duty shipping case. It features a Build Your Own (BYO) app selector where you can choose your own apps based upon your individual needs. The X-990 offers the same hardware as the X-880 but with a Professional App software license including most of the optional features included at a discounted price.

X-990 Industry-leading technology and innovations:

The world’s most advanced shaft alignment technology

For over 50 years, we have been providing highly accurate alignment systems to many different industries and applications. We started in the machine tool industry where tolerances are high and applications are difficult, and then 30 years ago we developed the world’s first 4-axis shaft alignment system. All of that experience and knowledge has gone into the design of the X-990 Wireless 5-axis Shaft Alignment System, resulting in the most accurate and yet easy-to use tool in its class.

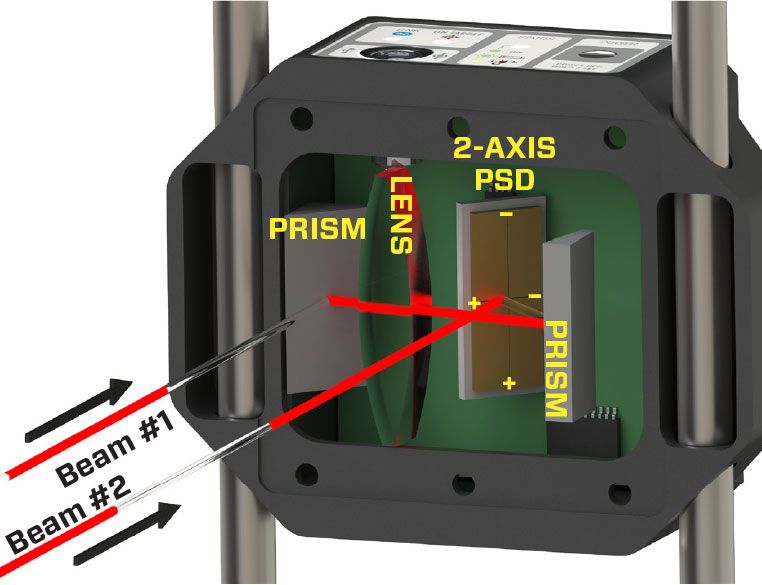

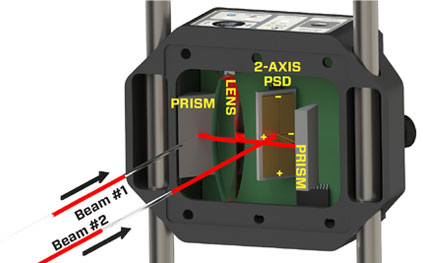

Advanced Unidirectional Dual-Beam™ Technology

This innovative technology provides an amazing ± 12º of angular range. Utilizing 2 unidirectional laser beams (2 lasers, 1 direction), it solves the rough-in (pre-alignment) problem with “cross-fire” lasers (2 lasers, 2 directions) and makes aligning machines amazingly fast and easy, especially on long-distance applications. The result? More jobs done in less time and happier managers!

No rough-in/pre-alignment needed

All “cross-fire” laser alignment systems require a rough-in (pre-alignment) of the machine before the system be able to take data. With Dual-Beam™ technology’s 2 unidirectional laser beams and a single 33 mm sensor, you don’t need to rough-in the motor to get it to take data. You get the same ±5 degrees of measuring range from 2 in. to 30 ft. (50 mm to 10 m), unlike the “cross-fire” kits that have virtually no measuring range beyond 5 ft. (1.5 m). So just slap on the brackets, laser and target and get to work!

Ultra-high fixed angular-measuring resolution, great for close-coupled applications

With “cross-fire” laser technology, the angular resolution varies with distance. Ironically it’s the close coupled applications that cause the most problems for angular accuracy for these systems. With our Dual-Beam™ technology, you get the same high angular resolution at 2 in. (50 mm) between heads as you get at 30 ft. (10 m), and our angular resolution is 15x higher than the highest angular spec.

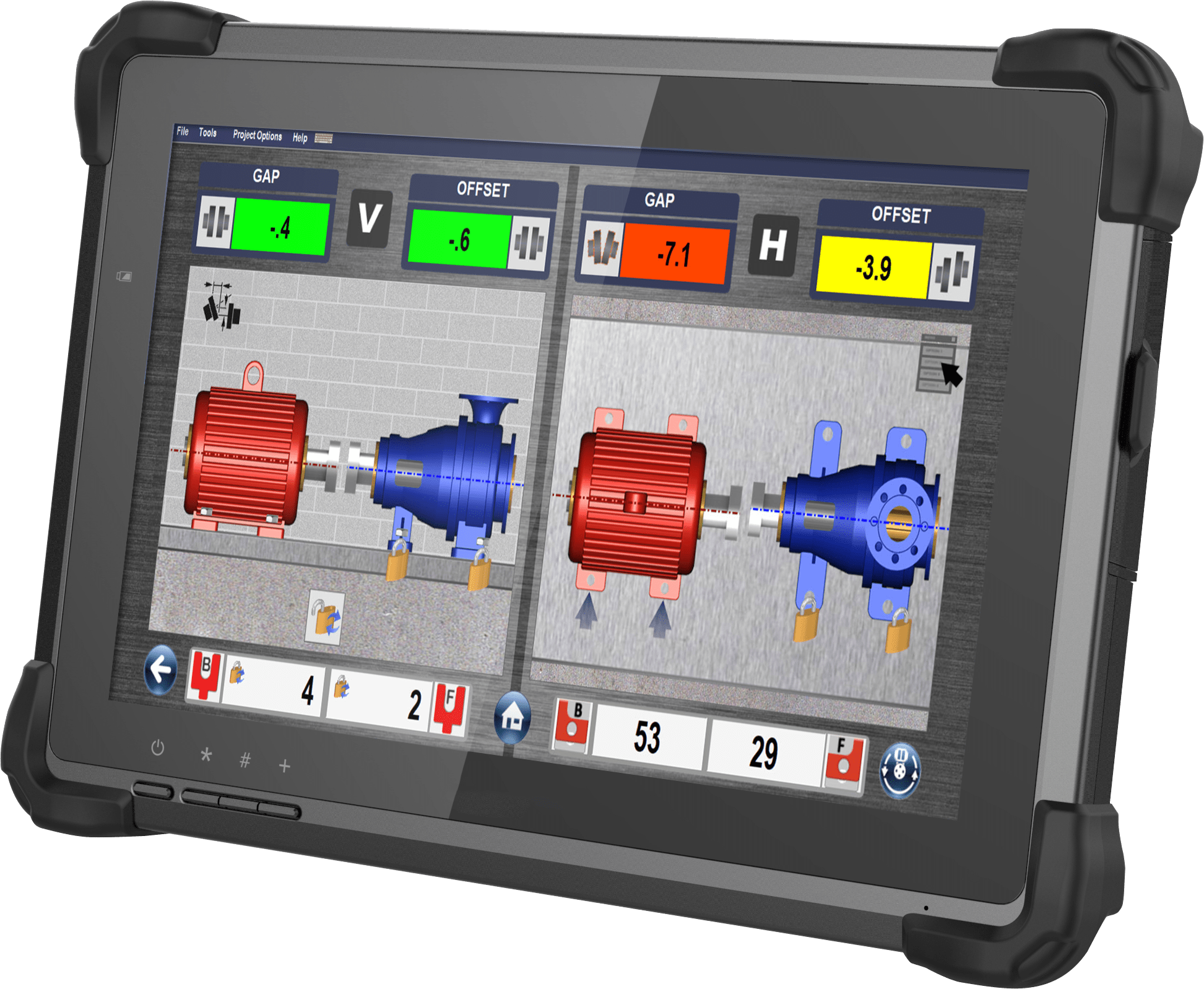

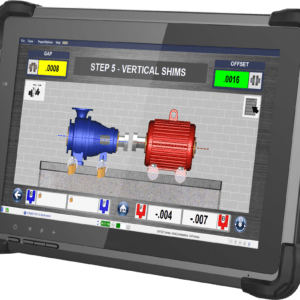

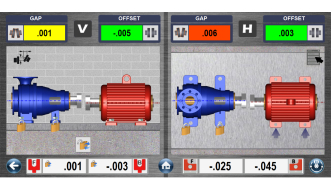

Duo-Plane™ realtime move screen: alignment corrections without shaft rotation

The Duo-Plane™ realtime move screen and 5-axis target allow you to view a live alignment screen for both the vertical and horizontal planes (4 axes) simultaneously without having to rotate the shafts. You can also leave the shafts at nearly any rotation angle. This is critically important on large machine applications where rotating the shafts is difficult or tightening the bolts can create horizontal movement of the machine, causing you to have to redo the alignment.

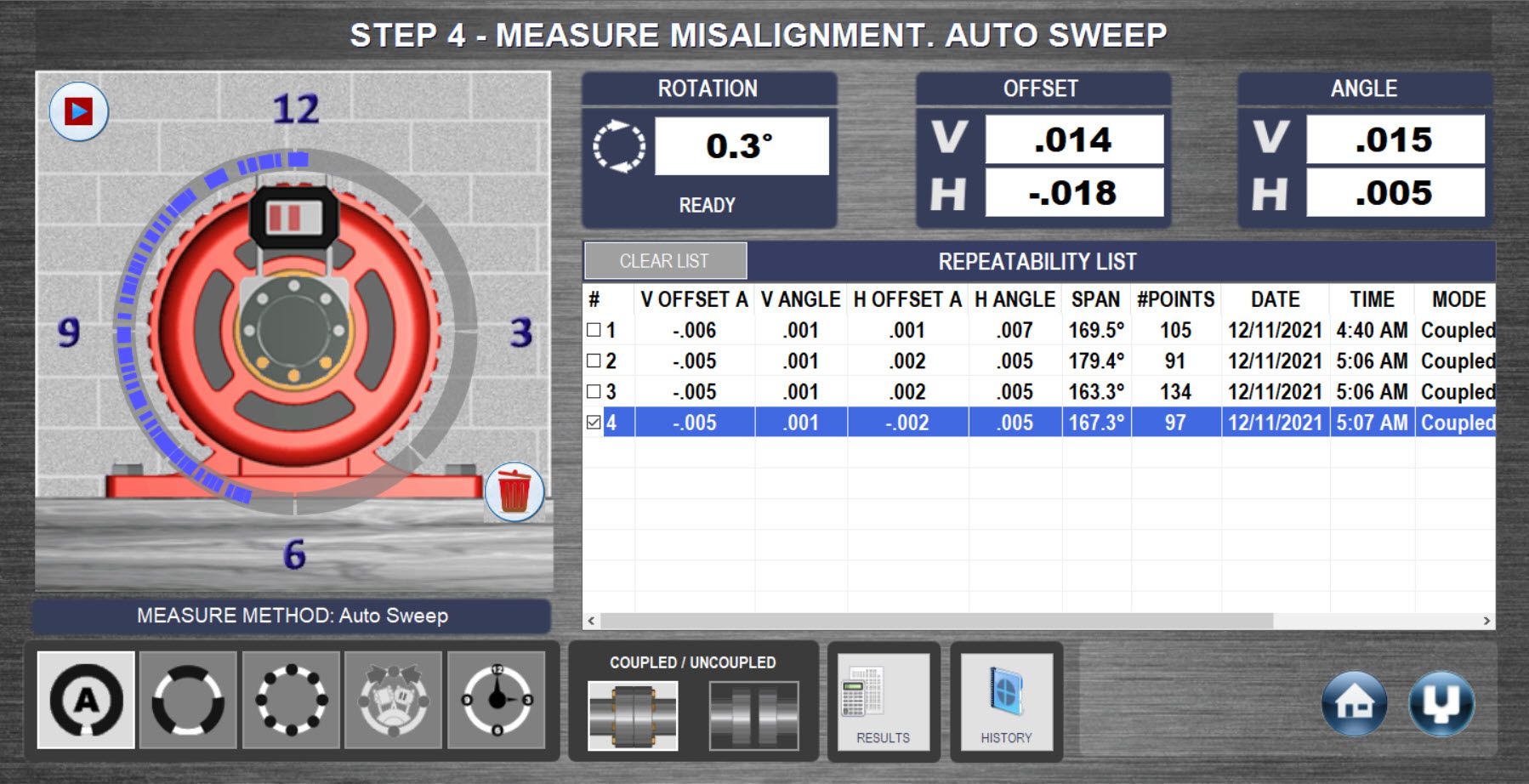

Ultra-accuracy means 2x faster alignments

Critical machinery demands the best the industry has to offer and the X-990 platform is up to the task. Super-linear PSD technology and 500-point linearization reduce the error rate to <0.15%, which is up to 15x higher than our competitors, giving you the confidence that the motor is aligned as accurately as possible. Higher accuracy also means better repeatability and more accurate shim calculations so you don’t have to keep doing the alignment over and over again. Shim Once, Move Once™!

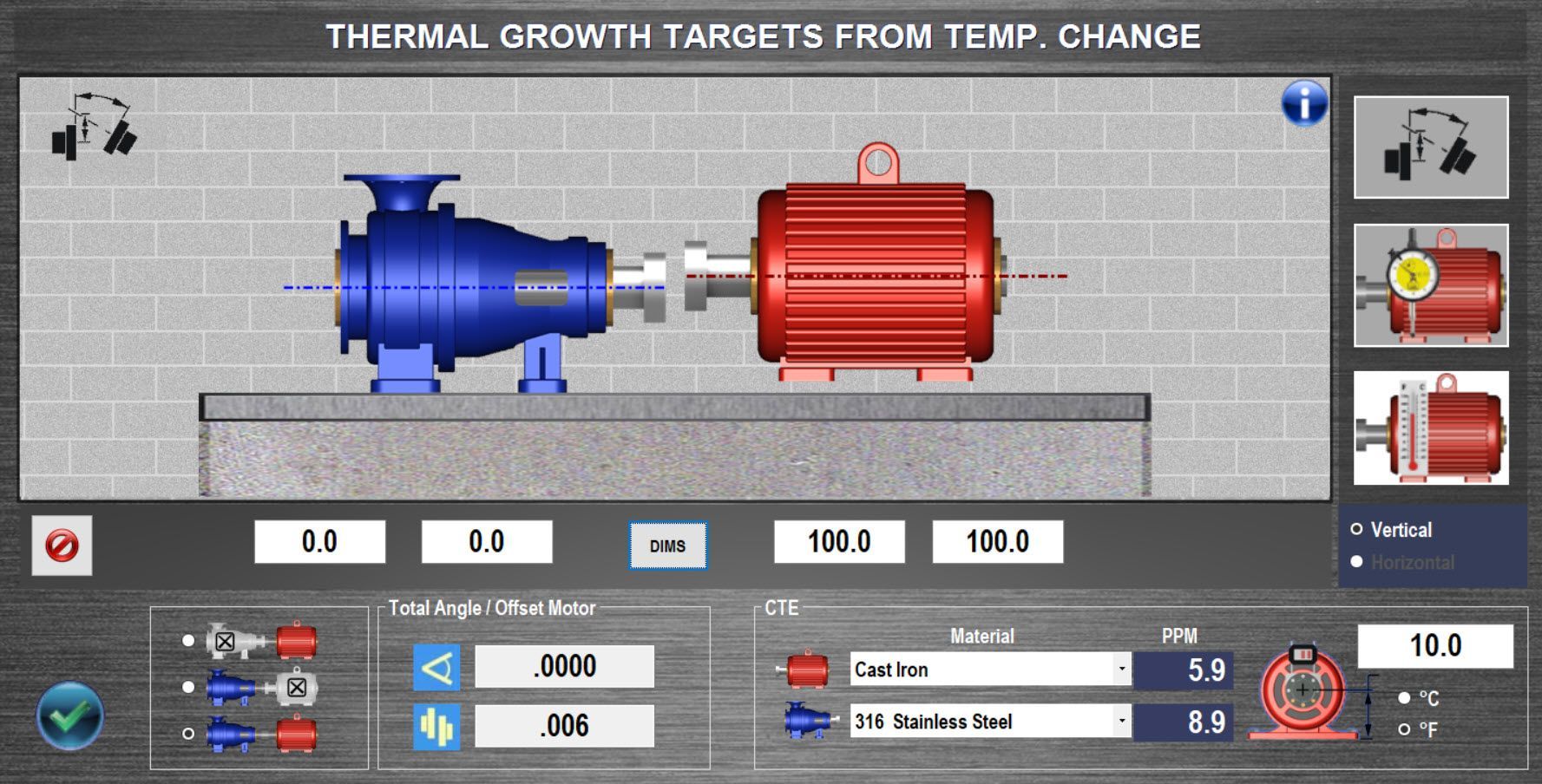

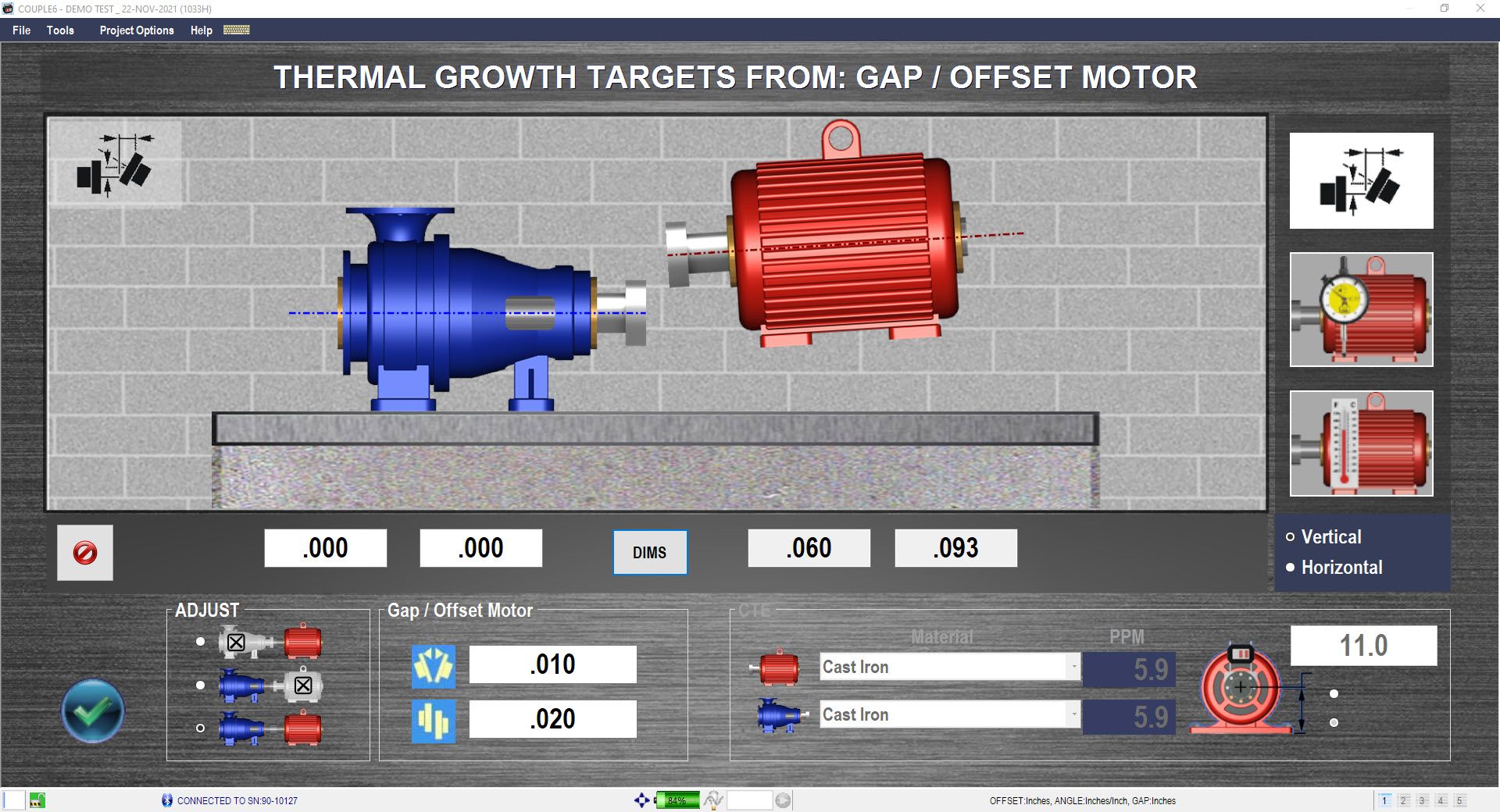

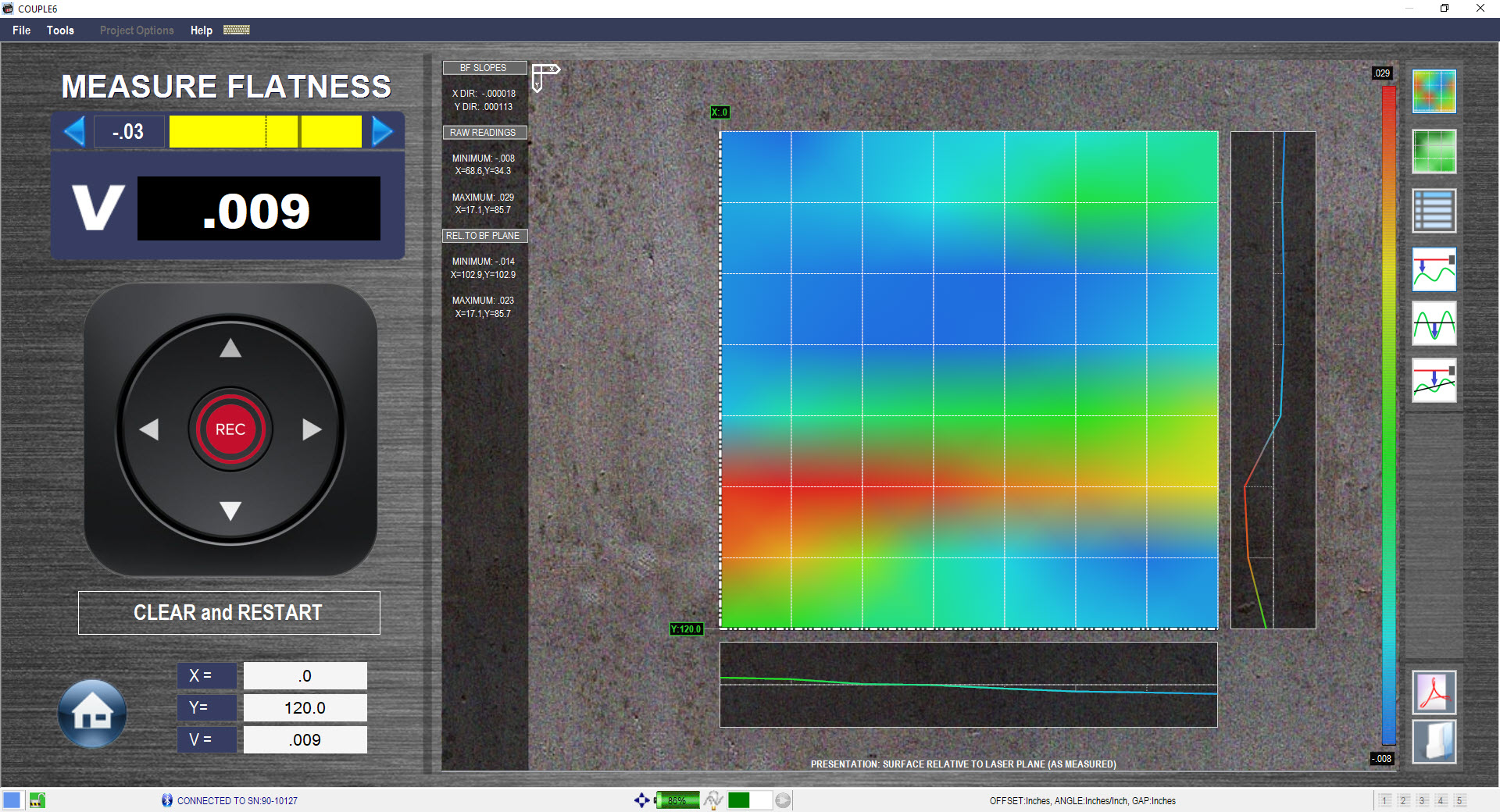

Flatness Measurement

Use the A-987 Bases with the shaft alignment laser and target, or the more precise L-730/L-750 Leveling Lasers with the A-1519-2.4ZB Target to measure the flatness of sole plates, compressor frames and other surfaces. Couple6 calculates the Best Fit plane for the data to provide the overall flatness values. A report shows the flatness TIR, a graph and a table of data.

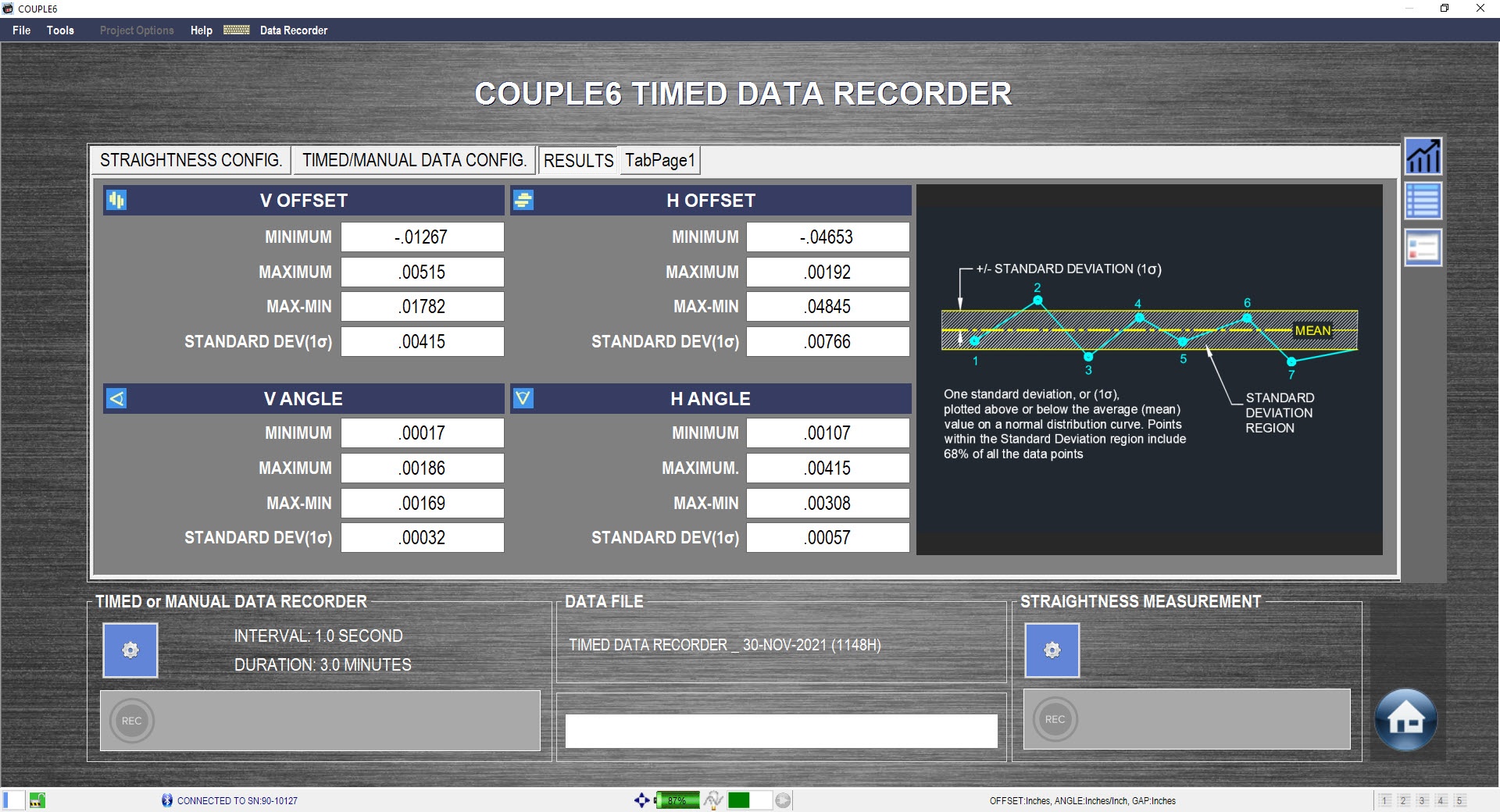

Straightness Measurement

Using our A-987 Bases, you can use our shaft alignment lasers to check the vertical/horizontal straightness of rails and surfaces. The Couple6 software calculates the Best Fit line for the data to provide the overall straightness values. A report shows the straightness TIR, a graph and a table of data.

Remote tech support

Utilizing the power of Windows, our tech support department can log on remotely to the tablet, via WiFi and the Internet.

Easy-Guide™ navigation with onboard manual and training videos

Our Couple6 software features our Easy-Guide™ navigation with its easy-to-follow, high-quality screens, leading users through each stage of the alignment. And if you forget how to do something, the manual and training videos are built right into the software! With software this easy to use, a lot of customers start using the X-990 kit right out of the box!

5-year unconditional warranty & low cost of ownership

With no hidden warranty fees like other systems, our 5 Year Unconditional Warranty is really that: no conditions! As long as you don’t damage it by abuse, then if something goes wrong, we replace or fix it. That’s it. We also don’t charge any software maintenance fees. Software updates are free for the life of the product!

Faster Setup, Faster Alignments

With the Hamar Laser® X-990 laser shaft alignment tool the bracket posts are pre-aligned to the brackets. Just attach the brackets, slide on the laser/target and adjust the laser into the window and in 2-3 minutes, you’re ready to take data!

Training included

All X-990 systems from Precise Reliability include 1-day of on-site training

Contact us for more information or demonstration.

Made in America