SDT Sonavu+ Ultrasound Camera

The SDT Sonavu+ ultrasound imaging camera makes finding air and vacuum leaks as well as electrical faults such as corona, partial discharge and tracking easy. You will be able to see, hear and record the leaks and electrical faults. With the included Sonavu Insights reporting software you can generate leak and electrical reports and put a dollar value to found leaks.

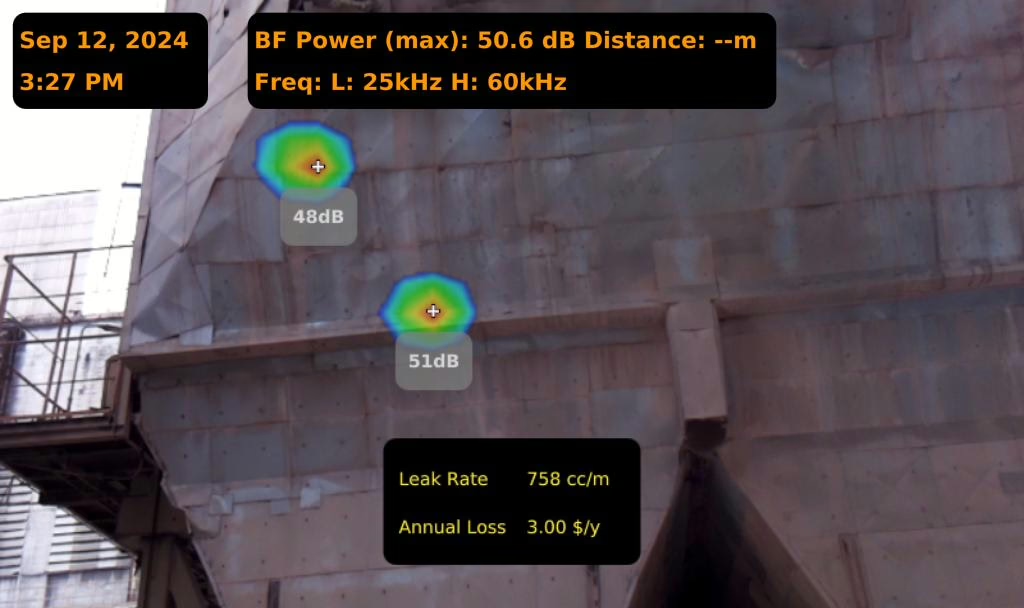

Compressed air and vacuum leak detection

Electrical reliability

Regular ultrasound inspections on your electrical equipment will reveal partial discharge at its earliest stages and keep workers safe.

Fugitive Emissions

What is a SonaVu+ acoustic imaging camera?

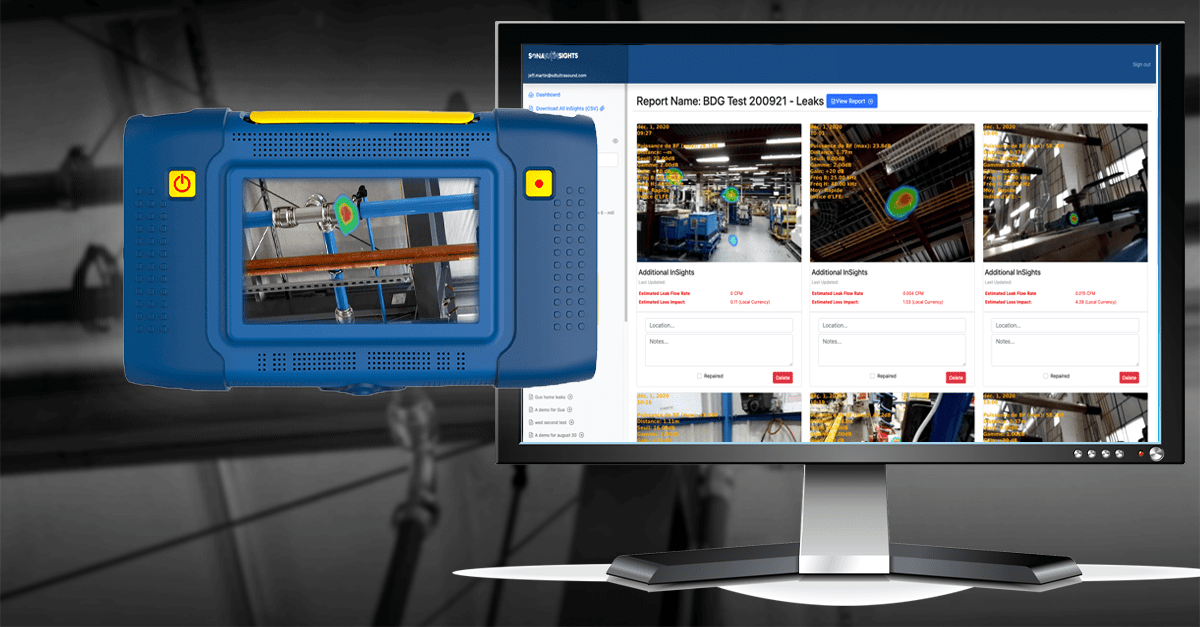

SonaVu Insights™

SonaVu InSights™ is a free web application for creating instant reports of compressed air leak and electrical asset surveys. The SonaVu InSights™ Image and Report Library is a secure place to store, organize, analyze, and prioritize your findings with your SonaVu+ Acoustic Imaging Camera. Document findings, prioritize repairs, estimate cost impact, eliminate energy waste, and save money with this free application.

Features for Compressed Air Leak Management with Sonavu insights™

- Upload unlimited leak survey data, images, and videos with lightning-fast speeds.

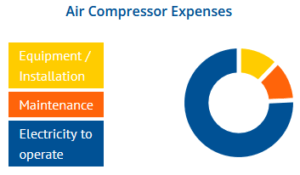

- Instantly calculate financial losses and savings impacts caused by leaks.

- Organize surveys by location, date & time, technician, smart naming conventions, notes.

- Manage compressor systems & compressed air electricity costs.

- Continuously integrate team discussion into a single living report.

Features for Managing Electrical Assets with SonaVu InSights™

- Upload and store unlimited survey data, images, and videos with lightning-fast speeds.

- Organize findings based on different parameters chosen by the technicians, managers, or planners.

- Determine types of Partial Discharge using Phase Resolved Partial Discharge (PRPD).

- Continuously integrate team discussion into a single living report.