Enhancing Dependability with Targeted Lubrication Strategies

It’s estimated that improper lubrication practices are attributed to 80% of bearing failures.

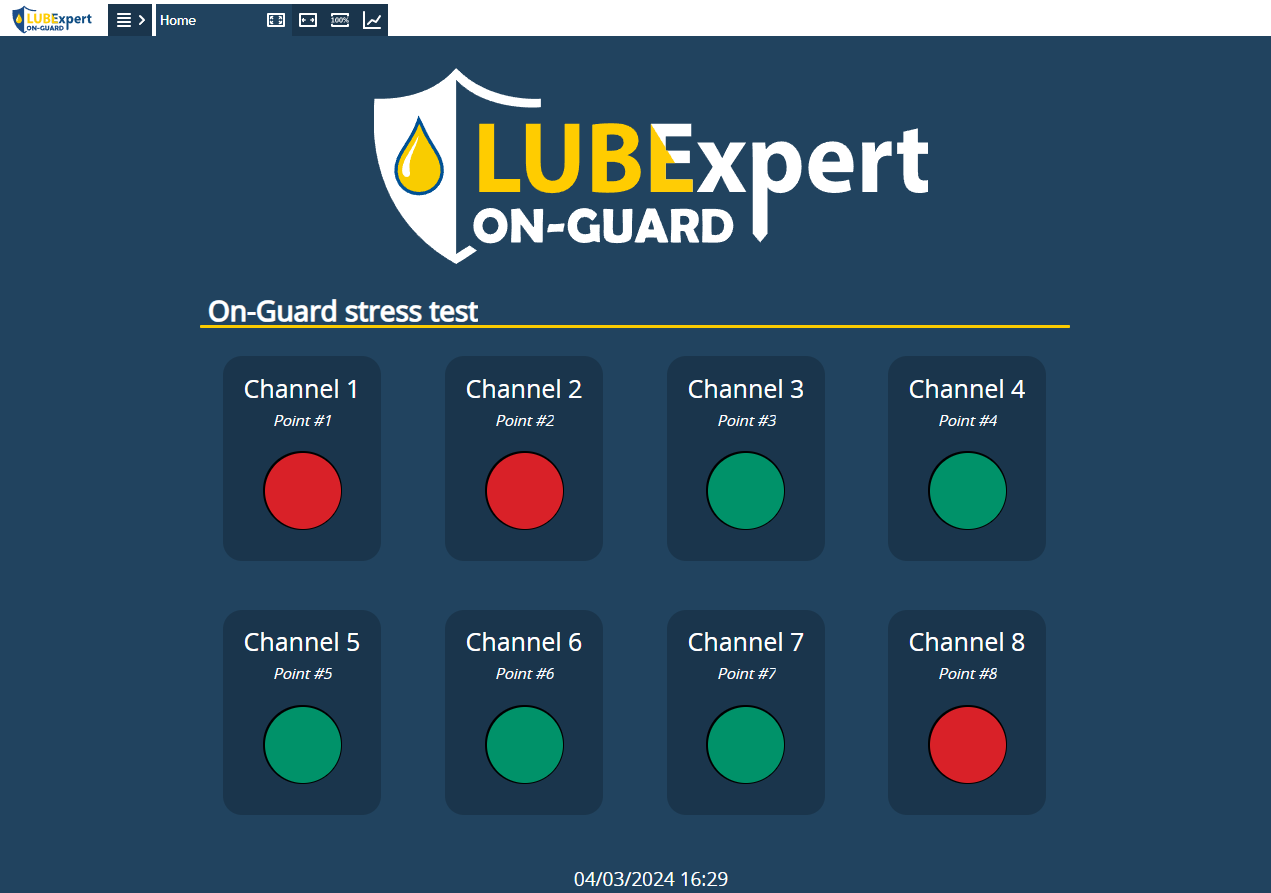

The LUBExpert ON-GUARD system removes the uncertainty in this vital maintenance process. By using ultrasonic technology to monitor the friction levels within rotating machinery, it ensures lubrication is applied only when necessary.

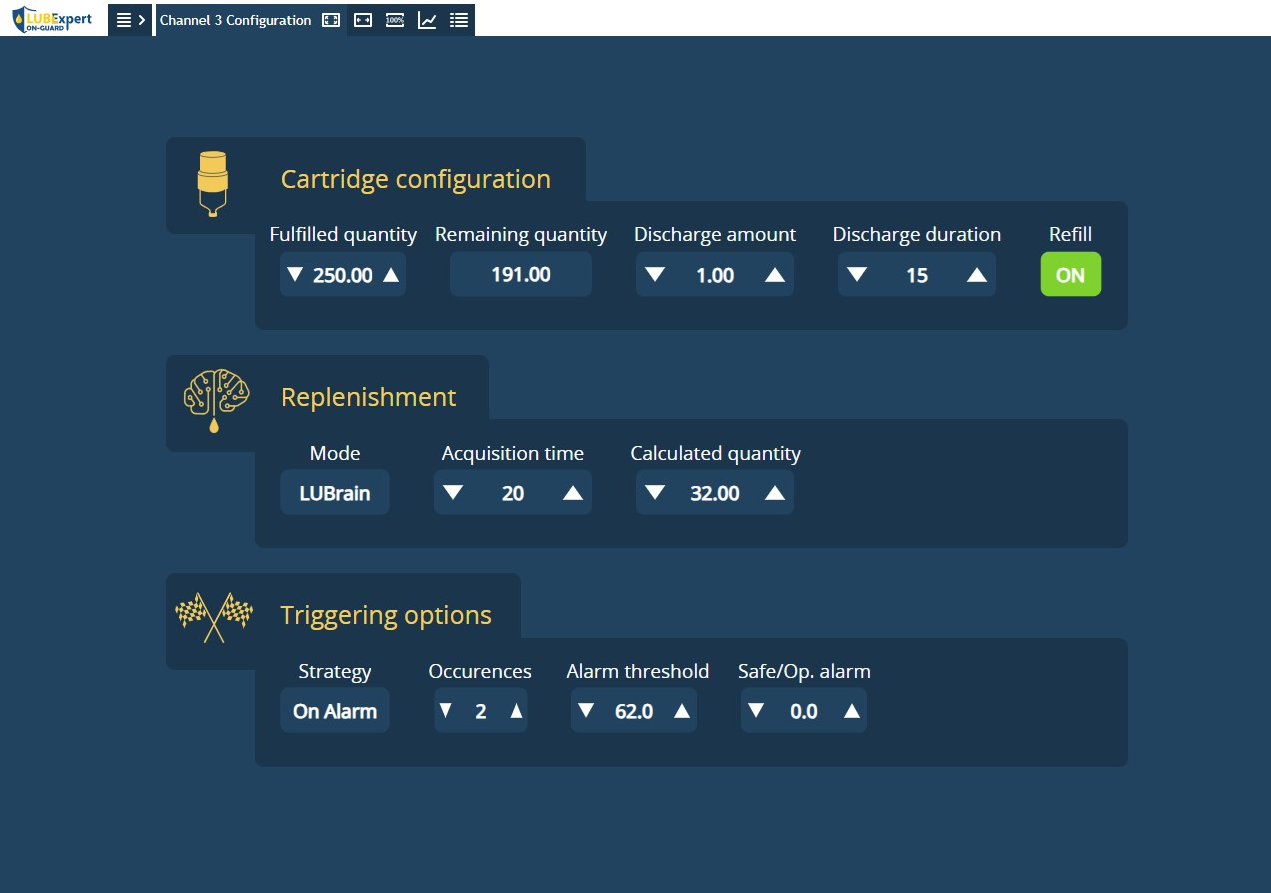

Make informed decisions with the data-driven capabilities of the LUBExpert ON-GUARD. Shift away from reliance on periodic schedules towards a maintenance model that values precision and accuracy above all. This proactive methodology serves as a wellness plan for your equipment, offering a custom, self-sufficient, and data-informed approach to prevent issues and bolster operational dependability.

Monitoring

Data is hosted by the system, displayed in separate charts organized per channel, and remains available/exportable to any client system compatible with Modbus TCP. The LUBExpert ON-GUARD offers the freedom to connect and control from anywhere, putting the power of efficient maintenance in the palm of your hands. Security remains key with the LUBExpert ON-GUARD. Your data is stored internally on the device.

Hardware

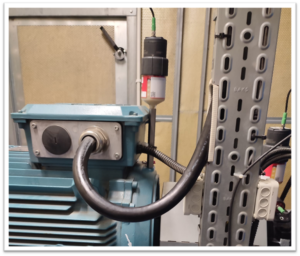

The LUBExpert ON-GUARD, equipped with 8 analog inputs and relay outputs, is supplied in a steel case available in different sizes to suit the user’s needs.

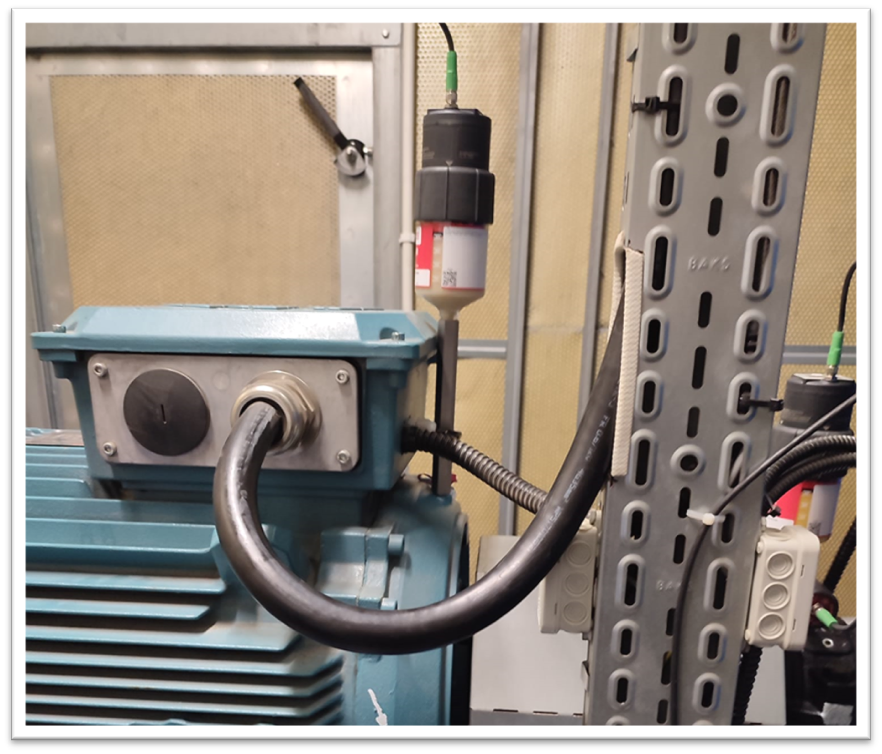

For simplified, straightforward use, the device is supplied in a kit containing:

- 8 pair sensor straight shielded cables + lubricator cables, varying in length from 5 to 30 meters

- 8 CONMONSense true 4-20mA sensors

- 8 lubricators

All you have to do is make the connections for the power supply and network, and connect the sensors and lubricators to the machine, and you’re ready to go!

Contact us for more information or demonstration.