Browser-Based Reporting Application Creates Reusable Compressed Air and Electrical Scan Reports in Seconds.

SonaVu InSights™ is a web application for creating instant reports of compressed air leak and electrical asset surveys performed with the SonaVu Acoustic Imaging Camera from SDT. Document findings, prioritize repairs, estimate cost impact, eliminate energy waste, and save money with this free application.

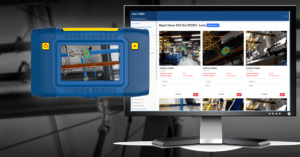

SonaVu™ is a multi-frequency acoustic imaging camera that blends visual and auditory senses to bring compressed air waste and failing or faulty electrical equipment into focus. Images and videos of compressed air leaks and electrical faults discovered using the SonaVu™ Acoustic Imaging Camera are uploaded to SonaVu InSights™ Report Library for seamless reporting and sharing.

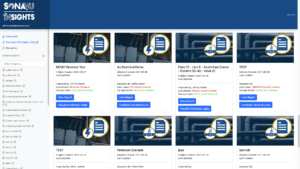

The SonaVu InSights™ Image and Report Library is a secure place to store, organize, analyze, and prioritize your findings with your SonaVu™ Acoustic Imaging Camera.

SonaVu InSights™ Compressed Air Leak Management

Energy waste, lost profits, poor product quality, and slower production output… a production managers worst nightmare! Is their reaction the same to compressed air leaks?

Used by millions of manufacturers around the world to power their processes, compressed air is often referred to the fourth utility, standing right beside gas, electricity, and water. It also happens to be the most expensive resource of the four utilities to produce.

Compressed air is often manufactured in-house so that manufacturers can maintain control over its uses, availability, abundance, and cost… or so they hope.

A Few Facts about Compressed Air

- Fact #1

Over a compressor’s lifetime, the energy costs associated with operating the compressor and manufacturing the compressed air equal around three times as much as the capital investment of the compressor and all associated costs (repairs, maintenance, installation). - Fact #2

Compressing air is not an energy efficient process – but it’s the only way to obtain the widely utilized resource. - Fact #3

35%-45% of the compressed air produced by a compressor is typically lost to leaks somewhere in the system. - Fact #4

When manufacturing processes are heavily reliant on compressed air, inconsistent or short supplies can result in sub-standard product quality, and longer production times.Half of this expense being lost to compressed air leaks is neither economically nor environmentally responsible, and it is plain to see that compressed air remains the most mis-managed of the four utilities. Either because manufacturers are unaware of their potential waste, or due to a lack of compressed air leak management software and ultrasound devices on-hand.

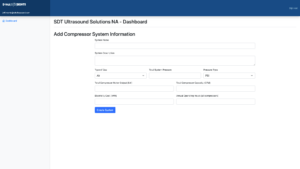

Manage Different Compressor Systems in Different Parts of your Facility

Compressor systems vary in size, output, components, demand, and wattage; and many facilities have multiple compressed air systems powering different processes. This information isn’t always readily available to all condition monitoring techs – but is vitally important for them to know for accurate calculation of losses (or savings) accumulated from compressed air leaks and their repairs.

How does SonaVu InSights™ Help Cut Down on Compressed Air Waste?

How does Acoustic Imaging Technology work for Compressed Air?

When compressed air passes from an area of high pressure (inside a compressed air line) through a leak to an area of low pressure (atmosphere on a manufacturing floor), ultrasonic turbulence is created. SonaVu™ uses its 112 digital mems sensors to detect these sources of ultrasonic turbulence. The leaks can then be recorded with the SonaVu™ and later be uploaded to SonaVu InSights™.

SonaVu InSights™ is a Complete Compressed Air Leak Management System

SonaVu™ can quickly scan sections of a compressed air system, capture images, videos, and measurements of the leaks that can later be uploaded to SonaVu InSights™ to generate fast, editable reports.

From the SonaVu InSights™ Application, leaks can be organized and documented in a number of ways (including cost savings impact of a leak). From there, leaks can be scheduled for repair based on priority parameters set out by the condition monitoring technician and maintenance planner.

Features for Compressed Air Leak Management

- Upload unlimited leak survey data, images, and videos with lightning-fast speeds.

- Instantly calculate financial losses and savings impacts caused by leaks.

- Organize surveys by location, date & time, technician, smart naming conventions, notes.

- Manage compressor systems & compressed air electricity costs.

- Continuously integrate team discussion into a single living report.

SonaVu InSights ™ For Electrical Systems Condition Monitoring

Unreliable electrical equipment and systems can cost manufacturers millions of dollars in unplanned downtime and repairs. These faulty electrical systems even have the potential to maim and kill. The key to reducing the amount of these costly and dangerous malfunctions is early detection.

With age, the insulation on electrical equipment breaks down. The undesired result in higher-voltage equipment is a phenomenon known as partial discharge (PD). Once this begins, the electrical equipment and components affected do not get better on their own… only worse, with rapidly increasing speeds. As the insulation of failing electrical equipment deteriorates, the process only happens faster and faster, and eventually maintenance will need to step in. At this stage, performing repairs and replacing damaged and corroded components is the only way to avoid catastrophic failure.

Another side effect of Partial discharge is the production of combustible gasses. When partial discharge is present in an enclosed space, like in an electrical cabinet, these gasses build up. Sudden increases in oxygen can cause an ignition resulting in a deadly and damaging phenomenon known as arc flash and arc blast.

SonaVu InSights™ Phased Resolved Partial Discharge (PRPD) Capabilities

Phase Resolved Partial Discharge (PRPD) is an algorithm for performing analysis of sound patterns produced by partial discharge. It is widely used in the field as a form of electrical systems fault analysis. Using the SonaVu™ Acoustic Imaging Camera, ultrasound inspectors can identify sources of partial discharge using airborne ultrasound signals in the frequency range of 25-40kHz. SonaVu™ can then display these ultrasound signals as Phase Resolved Partial Discharge alongside the acoustic image it produces. From here, inspectors can use the PRPD Pattern to determine the type of partial discharge they’re encountering.

The three most common partial discharge patters are corona partial discharge, surface partial discharge, and floating partial discharge.

Corona Partial Discharge is electrical discharge caused by the ionization of fluid such as air surrounding a conductor carrying a high voltage. It is present at high 90 degrees.

Surface partial discharge is much like Corona Partial Discharge, as it is electrical discharge caused by the ionization of fluid such as air surrounding a conductor carrying a high voltage. However, it is present at 270 degrees in addition to 90 degrees.

Floating partial discharge is also known as the floating electrode. It is an internal discharge that occurs within cavities of electrical insulation and increases as the material wears. Floating partial discharge is present at high 90 degrees (floating) as well as lower 270 degrees.

How Does SonaVu InSights™ help cut down Electrical Asset Failures

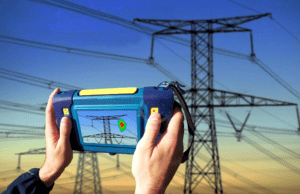

SonaVu™ Acoustic Imaging Camera has 112 highly sensitive digital mems sensors that can accurately detect ultrasound signals from over 50 meters (150 feet) away and transmit them into a visible image on screen.

How does Acoustic Imaging Technology work for detecting Partial Discharge?

The ionization of air molecules caused by partial discharge on failing electrical components creates ultrasonic turbulence in the air. SonaVu™ can detect this ionization from over 50 meters away. SonaVu™ can monitor power transmission and distribution lines just as well as it can monitor high voltage electrical cabinets.

Managing your Electrical Assets using SonaVu InSights™

Simply scanning your electrical assets with a SonaVu™ Acoustic Imaging Camera will reveal any defects and deterioration on the insulation that is present. To complete a survey, record findings, then upload them to the Report Library on SonaVu InSights™. Here they can be securely stored.

Electrical defects detected with the SonaVu™ can be organized based on notes, location, reporting technician, part number/equipment, date and time, and production process powered. From here they can be further prioritized and scheduled for repair based on the maintenance planners’ parameters.

Features for Managing Electrical Assets with SonaVu InSights™

- Upload and store unlimited survey data, images, and videos with lightning-fast speeds.

- Organize findings based on different parameters chosen by the technicians, managers, or planners.

- Determine types of Partial Discharge using Phase Resolved Partial Discharge (PRPD).

- Continuously integrate team discussion into a single living report.

Store, Organize, Analyze and Prioritize with SonaVu InSights™

Your ultrasound, and acoustic imaging data is just that… your data! It should be securely stored and properly organized, for easy access to the right people. Your data should be presented in a way that’s easy for the technician’s and maintenance planners to understand and navigate – making their job of analysis, and prioritizing repairs as seamless as possible.

The SonaVu InSights™ Image & Report Library

- Upload and store unlimited ultrasound and acoustic imaging data fast.

- Generate in-depth reports in the blink of an eye.

- Safely and securely store ultrasound and acoustic imaging data & reports.

- Organize, search and filter through your Image & Report library based on title, cost savings impact, notes, location, reporting technician, part number/asset, “repeat offenders”, date & time, repair status, and production process powered.

- Analyze data and reports based on chosen parameters (cost savings impact, and production process powered are the two most popular), then prioritize defects for repair.

Continuously Integrated Reporting

SonaVu InSights™ acts as one living document for a maintenance team, from technician to planner. Continuously integrated reporting builds cohesiveness and collaboration within a maintenance team. Update reports with team discussion, notes, priorities, maintenance plans and more!